Ballast for ships, marine, turbines and offshore structures

ULTIBALLAST

High density, solid and precast marine ballast for ships and offshore ballasting

What is ship ballast – Ultiballast?

Ballast is extra weight added to a ship or structure to keep it balanced in the water. Without marine ballast the vessel or structure would be highly unstable. Before the 1900's ships used solid ballast materials such as rocks and sand, which people had to shovel into and out of cargo holds. Today it is more commonplace to use concrete, iron or water to act as ship ballast. Tarmac has for many years provided ship ballast. Its concrete-based solution Ultiballast can be found in naval and commercial vessels, offshore structures and wind turbine foundations.

High or variable density ballast

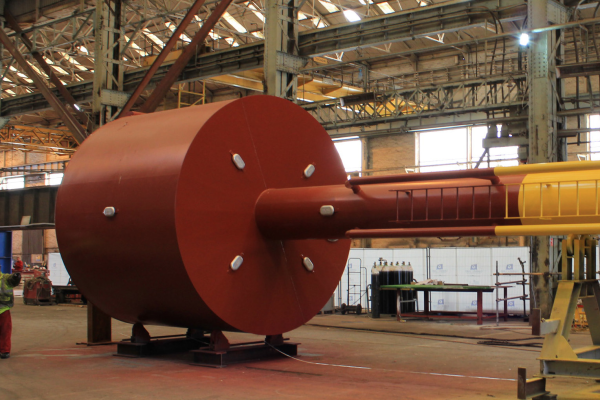

Ultiballast marine ballast solutions are flexible by design and easy to install. The ballast can be produced local to the project and is typically pumped from a mobile concrete pump through a network of pipelines into the receiving structure or vessel.

At the end of use the high-density concrete ballast can be safely removed and recycled as a normal concrete by-product.

Ultiballast is suitable ballast for use across a variety of sectors and applications.

SHIP BALLAST

Tarmac ship ballast allows precise placement of ballast with minimal access requirements, for improved flexibly and speed within production, docking and charter schedules.

Learn more

NAVAL BALLAST

Non-magnetic high density option ship ballast option up to 3.6 tonnes per cubic meter for mine counter measure scenarios and applications.

Learn more

RENEWABLES BALLAST

Our renewables ballast is a highly controlled, high-density ballast solution for construction of wind turbines, tidal generators and other on and offshore renewable energy applications.

Learn more

OIL & GAS BALLAST

Allows precise placement of ballast with minimal access requirements, for improved flexibly and speed within construction schedules and weather windows.

Learn more

History of marine ballast solutions from Tarmac

Ship and marine ballast design

The refinements made in product design and composition recognised the requirements and expectation for compliance not only from a marine design position, but also to include environmental considerations and whole life costs including recycling of Ultiballast at end of use. This approach along with the design improvements of the product allowed Tarmac to successfully enter and secure projects in the shipping, offshore renewable and oil & gas markets.

Tarmac has an enviable track record of working closely with clients, naval architects and design teams in the successful delivery of Ultiballast across a wide variety of ballasting projects.

Ship and marine ballast performance benefits

ULTIBALLAST Ship and Marine ballast - Tried, Tested and Proven

HMS Queen Elizabeth Aircraft Carrier - Aircraft Carrier Alliance & Royal Navy

HMS Prince of Wales Aircraft Carrier - Aircraft Carrier Alliance & Royal Navy

Six Type 45 Destroyers - BAE Surface Fleet & Royal Navy

LiDAR Buoy – Cammel Laird Shipbuilding Ltd/Babcock Wind Energy

Forties Alpha Satellite Platform – Offshore Group & BP

Royal Protection Vessel – Sultan of Brunei & Brunei Royal Navy

Marine ballast design

Ultiballast marine ballast is composed as a pre-blended and mixed combination of water and inorganic, non-toxic, granular ground fines and metals that can be produced in various density ranges to suit client or operational requirements.

During production and placement, the flow and workability compares to that of a traditional ready mixed concrete or cementitious grout. After placement Ultiballast sets to a solid mass.

Contact us

Our high-density ballast has a proven record of use in a range of marine and offshore applications.

Ultiballast complies with MARPOL and IBC code for use in chemical tanker vessels and is produced and installed by our experienced team, throughout the UK and Europe to suit client requirements and locations.